Products

Accessories and Consumables

Supermig i

Discover more

ELECTRODE HOLDER + CABLE 70MMQ 4M AX70

804126

GOUGING KIT

802666

GAS REGULATOR 2 MANOMETERS 32 L\min

722346

QUICK GAS CONNECTOR

804208

MT240 MIG TORCH 4M AQUA

742996

MT500 MIG TORCH 4M AQUA

742821

MT500 MIG TORCH 5M AQUA

722683

MT555 DC MIG TORCH 4M AQUA

742881

COIL ADAPTOR B-300

802486

ST26V 4M AX50 TIG TORCH

742058

When you ask for a Supermig, you’ll get a 5 process inverter welding machine to do whatever you want.

Switching from wire welding to gouging is quick and easy: select the process from the panel, connect the dedicated accessory and start working.

MIG-MAG/ FLUX MIG-MAG mode with synergic (material thickness selection) or manual operation. Operating mode with wire feeder unit or in CV mode.

MMA – PULSED MMA Direct current and pulsed welding. The adjustment of Hot Start and Arc Force allows to increase the quality and fluidity of the weld. Pulsed mode ensures excellent results with basic electrodes and in position welding.

Less spray and reworking, higher quality welding seam.

TIG TIG DC-lift welding. The precise strike in contact with the workpiece guarantees quality welding in steel, stainless steel, copper, etc.

GOUGING With carbon electrodes to eliminate excess material, for revised welding, for material cutting or workpiece preparation.

Resistant to dirt and dust thanks to the particular construction of the ventilation system which following a dedicated tunnel allows preservation of the electronic components, guaranteeing longer duration over time.

The double painting of the power boards guarantees further protection against humidity and dirt.

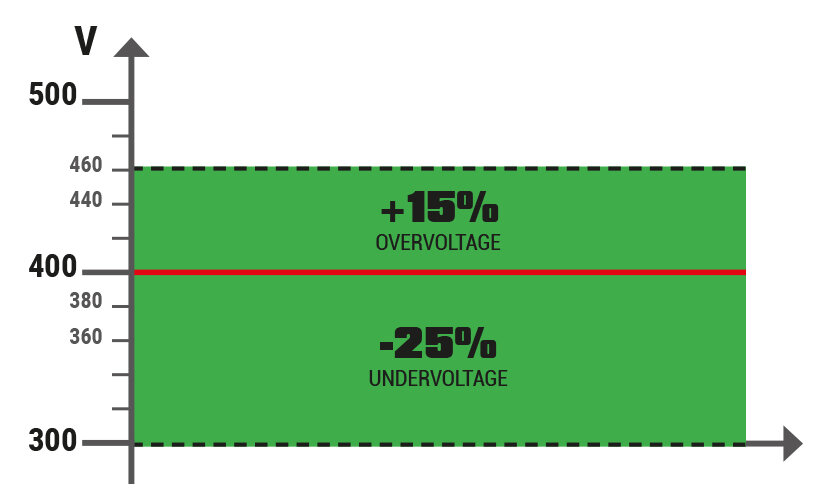

Particularly unstable or high impedance networks, when under load, lower the voltage with consequences on the stability and therefore on the quality of the weld.

The Supermig i range has a high tolerance of input voltages ensuring continuity, efficiency and quality in processing.

The compact and solid structure was designed for use in various work environments: from production to metal structural works, from building sites to mechanical workshops.

The wire feeder is robust and essential and has been designed to balance its weight during transport.

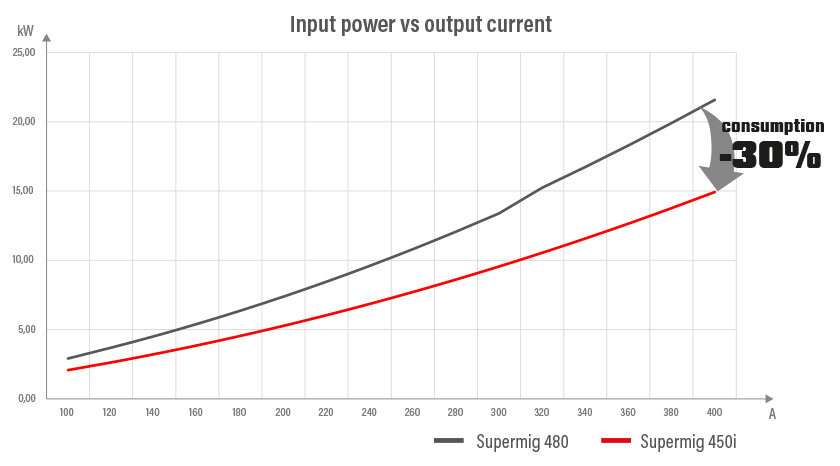

CONSUMPTION REDUCED BY 30%

Inverter technology drastically reduces energy consumption compared to traditional models.

INCREASE THE QUALITY OF THE PROCESSING

A more stable and controlled arc guarantees higher quality and speed in work. In fact, the electronic control allows you to accurately select the amperage required for processing. Thanks to the inverter technology, preset synergic curves are implemented to work on different materials and thicknesses.

The ONE TOUCH synergic adjustment reduces setting times and guarantees excellent work quality. Once the wire/gas programme has been selected, just set the thickness and start welding: the synergic curves are loaded automatically. The intelligent and automatic control of the arc, moment by moment, maintains high welding performance in all working conditions.

Pulsed mode ensures excellent results with basic, cellulosic electrodes and in positional welding. It is possible to set the two pulsing currents and their times for a reduced heat input and better arc control. Less spatter and rework, higher welding seam quality.

Oops! You can compare only products of the same category

Reached the maximum number of comparable products.