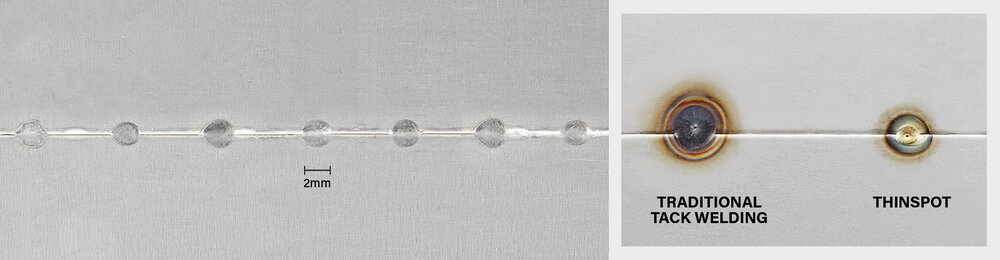

ThinSpot is a state-of-the-art function that, before welding, enables TIG tack welding of thin metal sheets in a easy, rapid and accurate way.

Particularly designed for use on stainless steel, it can also be used on Steel and Titanium.

Cutting edge arc control and the possibility to define the exceptionally reduced arc starting times makes it possible to considerably reduce the thermal load of each piece, reducing the risk of perforation caused by excessive overheating.

*Img: ThinSPOT and traditional TIG TACK welding times.

The result is a welding spot whose quality is similar to that of Laser welding in appearance and seal level.

Shorter spot welding times also guarantee increased respect of the basic material (especially Stainless Steel) reducing the possibility of corrosion whilst allowing faster execution speeds; this all works to the advantage of productivity which is higher compared to the traditional TIG spot welding method.

FEATURES:

- Rapid and accurate spot welding of sheet metal

- High operating speed

- Ease of use, easy to automate

- Reduced or no deformation thanks to the lower heat load

- Greater corrosion resistance for materials

- Possibility of joining this sheet metal with sheets of considerably different thicknesses