ADVANTAGES:

- Easier welding of spaced couplings

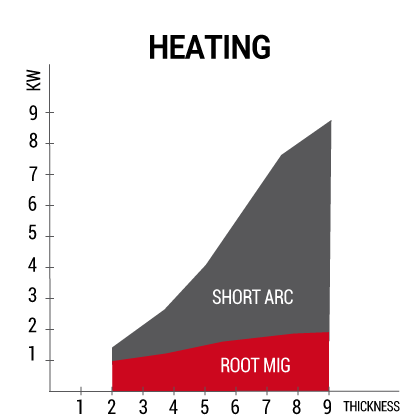

- Less power required compared to the short arc

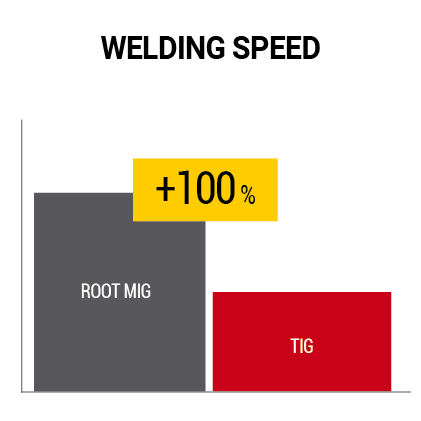

- Easier operations compared to the TIG

- Double operating speed compared to the TIG

- No ceramic support required

- Decreased deformation of material

- Reduced operating costs

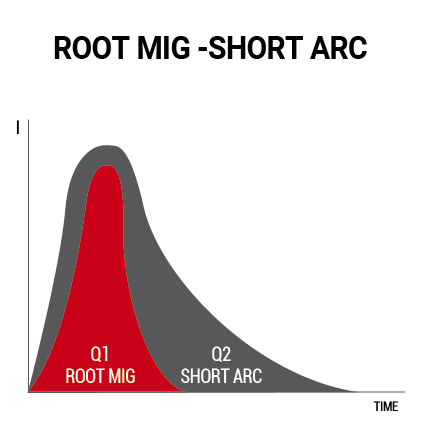

The characteristic waveform of the ROOT-MIG infers less transfer of power compared to the traditional short arc, making it much easier to fill the gaps between pieces and creating a faultless seam at the base of the coupling.

A first pass with endless advantages

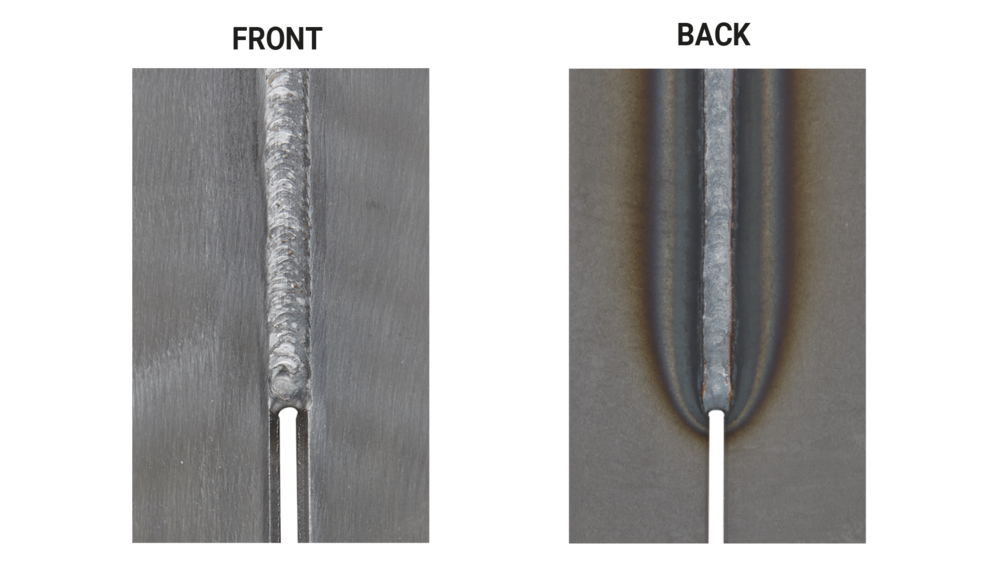

The result is very clear between the first pass in TIG and the first pass in ROOT MIG: double the productivity with comparable quality. Endless advantages: half the processing times, no preparation of pieces with ceramic supports, easy welding typical of the MIG-MAG process.

Greater control of the weld pool for lower thermal transfer of the ROOT-MIG (Q1) compared to SHORT ARC (Q2)